Tube spinning process: Recent advances and challenges

-

摘要:

The tube spinning process has attracted much attention because of its simple tooling and good surface finish. This review presents a comprehensive survey of the tube spinning process with a focus on different tube blank materials and spinning methods. The review aims to elaborate the research status of tube spinning process from the aspects of tube material, spinning method and processing performance, and act as a guide for researchers working on tube production and spinning process. In addition, the spinning process will produce large plastic deformation, which will lead to the change of the microstructure of the tube and change its mechanical properties. Therefore, the relationship between the mechanical properties of the tube blank and the spinning parameters is comprehensively expounded from the aspects of yield strength, elongation and material microstructure, and the element diffusion and interface bonding mechanism in the spinning process of the composite tubes are emphatically introduced. In particular, the latest development and trend of composite materials and composite spinning process in tube blank spinning process are discussed. The challenges and prospects of the development of the tube spinning process are put forward, and the direction for future research is pointed out.

Abstract:The tube spinning process has attracted much attention because of its simple tooling and good surface finish. This review presents a comprehensive survey of the tube spinning process with a focus on different tube blank materials and spinning methods. The review aims to elaborate the research status of tube spinning process from the aspects of tube material, spinning method and processing performance, and act as a guide for researchers working on tube production and spinning process. In addition, the spinning process will produce large plastic deformation, which will lead to the change of the microstructure of the tube and change its mechanical properties. Therefore, the relationship between the mechanical properties of the tube blank and the spinning parameters is comprehensively expounded from the aspects of yield strength, elongation and material microstructure, and the element diffusion and interface bonding mechanism in the spinning process of the composite tubes are emphatically introduced. In particular, the latest development and trend of composite materials and composite spinning process in tube blank spinning process are discussed. The challenges and prospects of the development of the tube spinning process are put forward, and the direction for future research is pointed out.

-

Key words:

- Tube blank /

- Spinning process /

- Materials /

- Spinning methods /

- Mechanical properties

-

[1] . Rammohan T, Mishra R. Studies on power spinning of tubes. International Journal of Production Research 1972; 10(4):351-364. [2] . Wong CC, Dean TA, Lin J, et al. A review of spinning, shear forming and flow forming processes. International Journal of Machine Tools and Manufacture 2003; 43(14):1419-1435. [3] . Allwood JM, Kawai, K. A review of the mechanics of metal spinning. Journal of Materials Processing Technology 2010; (1):210. [4] . Xia QX, Xiao GF, Long H, et al. A review of process advancement of novel metal spinning. International Journal of Machine Tools and Manufacture 2014; 85:100-121. [5] . Lang LH, Liu KN, Zhang WS, et al. New progress in flexible medium forming process of sheet/tube. Precision Forming Engineering 2016; 8 (5):15-22[Chinese]. [6] . Xu W, Zhao X, Ma H, et al. Influence of roller distribution modes on spinning force during tube spinning. International Journal of Mechanical Sciences 2016; 113:10-25. [7] . Li ZX, Rezaei S, Wang T, et al. Recent advances and trends in roll bonding process and bonding model:A review. Chinese Journal of Aeronautics, 2023; 36(4):36-74. [8] . Hamed Z, Alireza FA, Mojtaba S. Enhanced finite element analysis of material deformation and strain distribution in spinning of 42CrMo steel tubes at elevated temperature. Materials & Design 2013; 47:234-242. [9] . Takahashi Y, Kihara S, Nagamachi T, et al. Effects of neck length on occurrence of cracking in tube spinning. Procedia Manufacturing, 2018; 15:1200-1206. [10] . Hu Z, Wang C. Effect of tube spinning with subsequent heat-treatment on performance and microstructure evolution of T250 maraging steel. Journal of Iron and Steel Research International 2012; 19(5):63-68. [11] . Miscandlon J, Tuffs M, Halliday TS, et al. Effects of flow forming parameters on dimensional accuracy in Cr-Mo-V steel tubes. Procedia Manufacturing 2018; 15:1215-1223. [12] . Tan XP, Li SK, Fan GJ. Cause analysis and process optimization of bottom crack in hot spinning forming of 34CrMo4 steel pipe. Metal Processing (Hot Processing) 2023; (7):106- 110[Chinese]. [13] . Zhang JF, Yan BJ, Zhao CJ, et al. Orthogonal optimization of ball spinning process parameters of AISI-304 stainless steel thin-walled tube. Hot Processing Technology 2024; 3:100-104[Chinese]. [14] . Zhang ZS, Liu JC, Liu H, et al. Research progress and development trend of thermomechanical treatment of aluminum alloy Light Alloy Processing Technology 2023; 51 (2):1-14.[Chinese]. [15] . Liu JA. A brief discussion on the development trend of aluminum alloy materials and processing industry and technology (I). Aluminium Fabrication 2012; 1:13-18[Chinese]. [16] . Liu JA. A brief discussion on the development trend of aluminum alloy materials and processing industry and technology (II). Aluminium Fabrication 2012; 2:4-13[Chinese]. [17] . Rasooli M, Moshref-Javadi M, Taherizadeh A. Investigation of ultrasonic vibration effects on the microstructure and hardness of aluminum alloy 2024 tube spinning parts. The International Journal of Advanced Manufacturing Technology 2015; 77(9-12):2117-2124. [18] . Nakasato S, Kobayashi J, Itoh G. Hot spinning formability of aluminum alloy tube. Procedia Manufacturing, 2018; 15:1263-1269. [19] . Liu J, Cheng YS, Chan SW, et al. Microstructure and mechanical properties of 7075 aluminum alloy during complex thixoextrusion. Transactions of Nonferrous Metals Society of China 2020; 30(12):3173-3182. [20] . Zhou B, Lu S, Xu KL, et al. Hot cracking tendency test and simulation of 7075 semi-solid aluminium alloy. Transactions of Nonferrous Metals Society of China 2020; 30(2):318-332. [21] . Baek MS, Euh K, Lee KA, et al. Microstructure, tensile and fatigue properties of high strength Al 7075 alloy manufactured via twin-roll strip casting. Journal of Materials Research and Technology 2020; 9:9941-9950. [22] . Zheng FL, Chen HS, Wang WS, et al. Microstructure and mechanical properties of AlZn- Mg-Cu (7075) alloy tubes by power stagger spinning. Chinese Journal of Nonferrous Metals 2023; 33(8):2287-2302 [23] . Zhang RY, Wang EL, Zhao GY, et al. Effects of process parameters on elongation during hot power backward spinning for 7075 cast aluminium alloy tube. Advanced Materials Research 2013; 753-755:183-186. [24] . Zhang RY, Tu SJ, Zhao GY, et al. Evolution regularity of temperature filed in hot power backward spinning for 7075 cast aluminium alloy tube. Advanced Materials Research 2013; 774-776:1170-1173. [25] . Molladavoudi HR, Djavanroodi F. Experimental study of thickness reduction effects on mechanical properties and spinning accuracy of aluminum 7075-O during flow forming. International Journal of Advanced Manufacturing Technology 2011; 52:949-957. [26] . Liu CY, Wang Q, Jia YZ, et al. Microstructures and mechanical properties of Mg/Mg and Mg/Al/Mg laminated composites prepared via warm roll bonding, Materials Science Engineering A 2012; 556:1-8. [27] . Zhang TT, Wang WX, Cheng XQ, et al. Microstructure and Micro/nano Mechanical Properties of Magnesium Alloy Tube by Power Spinning. Rare Metal Materials and Engineering 2018; 47(5):1573-1577 [28] . Zheng F, Chen H, Zhang Y, et al. Microstructure evolution and corrosion resistance of AZ31 magnesium alloy tube by stagger spinning. International Journal of Minerals, Metallurgy and Materials 2022; 29(7):12. [29] . Faraji G, Yavari P, Aghdamifar S, et al. Mechanical and microstructural properties of ultra-fine grained AZ91 magnesium alloy tubes processed via multi pass tubular channel angular pressing (TCAP). Journal of Materials Science Technology 2014; 30(2):134-138. [30] . Xiao G, Zhang Y, Huang Y, et al. Grinding mechanism of titanium alloy:Research status and prospect. Journal of Advanced Manufacturing Science and Technology 2021; 1(1):2020001. [31] . Yue CX, Xie ZL, Liu XL, et al. Chatter prediction of milling process for titanium alloy thin-walled workpiece based on EMD-SVM. Journal of Advanced Manufacturing Science and Technology 2022; 2(2):2022010. [32] . Yang Q, Cheng C, Elaty AA, et al. Effects of punch size, magnetic field, and magnetorheological elastomers medium on forming T-shaped thin-walled Inconel 718 tubes. Chinese Journal of Aeronautics 2020; 35(1):226-237. [33] . Gao P, Yu C, Fu MW, et al. Formability enhancement in hot spinning of titanium alloy thin-walled tube via prediction and control of ductile fracture. Chinese Journal of Aeronautics 2022; 35(2):320-331. [34] . Yang YT, Ren CJ, Cao XW, et al. Research on spinning process of Ti1300 alloy cylindrical parts with steps. Aerospace Material Process 2014; 44 (3):88-90[Chinese]. [35] . Guo J, Zhan M, Yang H, et al. Research progress of rolling-spinning forming of titanium alloy cylindrical parts. Progress of materials in China 2016; 35(4):275-283+261[Chinese]. [36] . Hui J, Feng ZX, Fan WX, et al. The influence of power spinning and annealing temperature on microstructures and properties of Cu-Sn alloy. Materials Characterization 2018; 144:611-620. [37] . Li B, Yuan QW, Jin K, et al. GH625 superalloy tube necking spinning forming numerical simulation and experimental study. Aeronautical Manufacturing Technology 2017; (18):36-42[Chinese]. [38] . Wen HB. Numerical simulation of ball spinning forming of Ni-Ti-Nb shape memory alloy tube[dissertation]. Harbin:Harbin Engineering University, 2016[Chinese]. [39] . Niguse KA, David M, Jan I. Investigation of fiber content evaluation methods of carbon fiber reinforced thermoplastic composites. Journal of Thermoplastic Composite Materials 2024; 37(1):128-145. [40] . Zhu G, Sun G, Liu Q, et al. On crushing characteristics of different configurations of metal-composites hybrid tubes. Composite Structure 2017; 175:58-69. [41] . Han Z, Li H, Xu X, et al. Crushing characteristics of aluminum/CFRP/aluminum hybrid tubes prepared by spinning forming. Composite Structures 2020; 249:112551. [42] . Samandari M, Abrinia K, Akbarzadeh A, et al. Properties and mechanism of Al/St bimetal tube bonding produced by cold spin-bonding (CSB) process. Transactions of the Indian Institute of Metals 2017; 70(10):2673-2682. [43] . Yang YY, Cheng HS, Jun Z, et al. Study on interface behavior and mechanical properties of Al/Cu laminated tubes fabricated by strong staggered spinning at room temperature. Journal of Materials Research and Technology 2023; 25:7307-7324. [44] . Xu W, Zhang Z, Huang K, et al. Effect of heat treatment and initial thickness ratio on spin bonding of 3A21/5A03 composite tube. Journal of Materials Processing Technology 2017; 247:143-157. [45] . Xu WB, Yang YY, et al. Optimization of spinning parameters of 20/316L bimetal composite tube based on orthogonal test. Science and Engineering of Composite Materials 2020; 27(1):272-279. [46] . Cheng YL, Cheng HS, Zhou J, et al. Micro-nano interface structure and mechanical characteristics of thin wall Cu/Al composite tubes prepared by strong staggered spinning. Materials Characterization 2023; 206(PA):113405. [47] . Xu WC, Zhao XK, Ma H, et al. Influence of roller distribution modes on spinning force during tube spinning. International Journal of Mechanical Sciences 2016; 113:10-25. [48] . Xue KM, Wang Z, Lu Y, et al. Elasto-plastic FEM analysis and experimental study of diameteral growth in tube spinning. Journal of Materials Processing Technology 1997; 69:172- 175. [49] . Shan D, Yang G, Xu W, et al. Deformation history and the resultant microstructure and texture in backward tube spinning of Ti-6Al- 2Zr- 1Mo-1V. Journal of Materials Processing Technology 2009; 209(17):5713-5719. [50] . Zheng JB, Shu XD, Chen SY, et al. Forming quality analysis of Mg-Al composite pipes of multi-pass power spinning. ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE). 2022. [51] . Sivanandini M, Dhami SS, Pabla BS, Flow forming of tubes-a review, International Journal of Engine Research 2012; 3:1-11. [52] . Lin Y, Qian S, Chen X, et al. Staggered spinning of thin-walled Hastelloy C-276 cylindrical parts:Numerical simulation and experimental investigation. Thin-Walled Structures 2019; 140:466-476. [53] . Shi N. Microstructure evolution and interface bonding mechanism of 6061Al/AZ3lbMg composite tube by stagger spinning[dissertation]. Taiyuan:Taiyuan University of Technology, 2020[Chinese]. [54] . Yang Z, Xu W, Wu H, et al. Enhancing hoop strength of titanium alloy tube by cross spinning. International Journal of Machine Tools and Manufacture 2020; 152:103530-103530. [55] . Wang T, Wang DP, Liu G, et al. Investigations on the nano crystallization of 40Cr using ultrasonic surface rolling processing. Apply Surface Science 2008; 255:1824-1829. [56] . Zhang YQ, Zhan M, Fan XG, et al. Forming of pure titanium tubes by combined spinningultrasonic surface rolling process:Microstructure and mechanical properties. Journal of Manufacturing Processes 2023; 105:70-83. [57] . Lei ZN, Gao PF, Wang XX, et al. Analysis of anisotropy mechanism in the mechanical property of titanium alloy tube formed through hot flow forming. Journal of Materials Science and Technology 2021; 86(27):77-90. [58] . Zhan M, Yang H, Guo J, et al. Review on hot spinning for difficult-to-deform lightweight metals. Transactions of Nonferrous Metals Society of China 2015; 25(6):1732-1743. [59] . Gao PF, Li M, Zhan M, et al. Circumferential twist in flow forming of tubular parts:Characterization, understanding and control. Journal of Manufacturing Processes 2021; 65:144-152 [60] . Jin X, Xu WC, Yang GJ, et al. Microstructure evolution and strengthening mechanisms of Mg- 6Gd-4Y-0.5Zn-0.5Zr alloy during hot spinning and aging treatment. Materials Science Engineering A 2021; 827:142035. [61] . Ma H, Xu W, Jin CB, et al. Damage evaluation in tube spinnability test with ductile fracture criteria. International Journal of Mechanical Sciences 2015; 100:99-111. [62] . Xu W, Wu H, Ma H, et al. Damage evolution and ductile fracture prediction during tube spinning of titanium alloy. International Journal of Mechanical Sciences 2018; 135:226-239. [63] . Mohebbi SM, Akbarzadeh A. Fabrication of copper/aluminum composite tubes by spinbonding process:experiments and modeling. The International Journal of Advanced Manufacturing Technology 2011; 54(9-12):1043-1055. [64] . Zhang Z, Xu W, Shan D. An analytical model on spin-bonding of composite tube. Procedia Engineering 2014; 81(C):2024-2029. -

下载:

下载:

京公网安备 11010502036328号 京ICP备17033152号

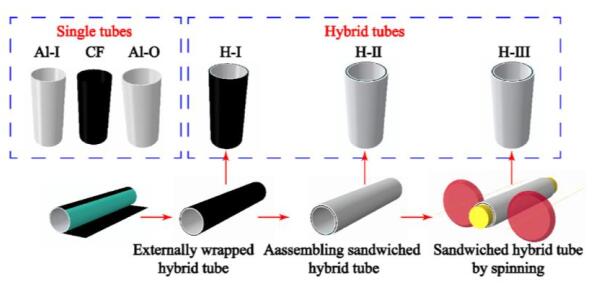

京公网安备 11010502036328号 京ICP备17033152号